Ship-To-Shore Power Cables

Complies With 11310.3BOPNAVINST 11310.3B

Flexible THOF Ship-To-Shore Power Cables

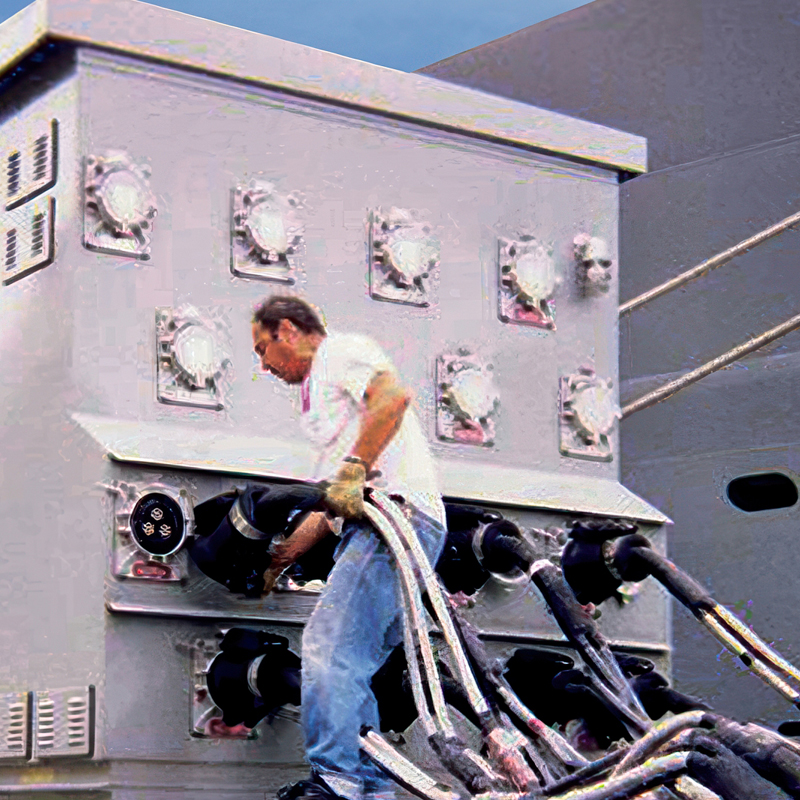

Ship-to-shore power cables (also called shore power, cold ironing, or OPS – Onshore Power Supply) helps the environment by allowing military, commercial or leisure ships to plug into the local electrical grid while docked, instead of running their diesel engines to generate onboard electricity.

AmerCable manufactures highly Reliable Ship-To-Shore Power Cables in two constructions – Enhanced THOF and Enhanced Plus THOF.

- Complies with OPNAVINST 11310.3B

- ICEA S-75-381: Portable and Power Feeder Cables for Use in Mines and Similar Applications

Benefits

- Reduced hours on auxiliary engines

- Reduced Air Pollution – marine diesel enginers are less efficient and high polluters

- Lower Greenhouse Gas Emissions

- Improved Local Air Quality

- Reduced Noise Pollution – ausiliarry engines generally product significant noise and vibratio

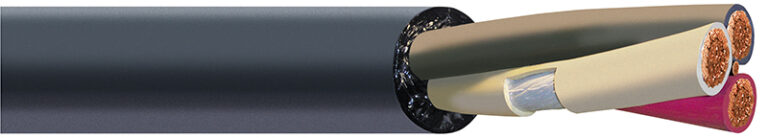

Enhanced THOF

A flexible 600V cable used for ship-to-shore power. Replaces former MIL-C 915 design for most applications.

Features

- Complies with OPNAVINST 11310.3B n Integral filled inner jacket for enhanced toughness and crush resistance

- Water migration minimized

- Mold-cured reinforced jacket for enhanced abrasion and tear resistance

- Pigment colored jacketed singles for phase identification

- Tinned copper conductors for reduced corrosion

- Indent printed for long term identification

- Functional testing to ensure flexibility in both summer and winter conditions

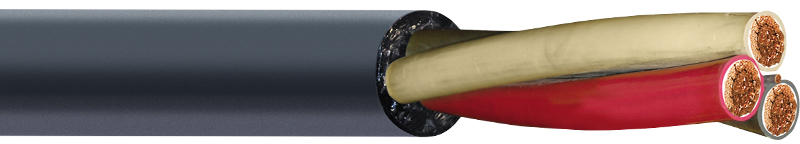

Enhanced Plus THOF

An extra-tough, flexible 3/C 600V ungrounded power cable specifically designed for naval shore-to-ship and other pier side power applications. Enhanced Plus THOF is specially designed for additional sunlight and weather resistance.

Features

- Complies with OPNAVINST 11310.3B

- Integral filled inner jacket for enhanced toughness and crush resistance

- Water migration minimized

- Mold-cured reinforced jacket for enhanced abrasion and tear resistance

- Jacketed singles for increased resistance to sunlight and weather

- Pigment colored jacketed singles for phase identification

- Tinned copper conductors for reduced corrosion & flexibility

- Jacket is indent printed for long-term identification

- Functional testing to ensure flexibility in both summer and winter conditions

Benefits Include

- Reduced hours on auxiliary engines

- Reduced Air Pollution – marine diesel enginers are less efficient and high polluters

- Lower Greenhouse Gas Emissions

- Improved Local Air Quality

- Reduced Noise Pollution – ausiliarry engines generally product significant noise and vibration